Imagine going on a long drive in the countryside; you cruising along a quiet, winding road. As you drive, you hear the wind catching the trees in gusts. There’s a brook running by the side of the road. You draw in a deep breath, and note with great satisfaction that the air is rich with the smell of ripening grain. A beautiful setting, isn’t it?

Fast-forward to 50 years from now and this long drive may just remain a figment of our imagination. It’s time to face the grim reality. As humans of the early 21st century, we are addicted to fossil fuels. From our early morning tea, the car we drive to the late-night TV show binge, every aspect of our existence is run by coal, oil and natural gas. They are prerequisites for the running of any industry, business or public transport comprehensible. In the not-so-distant future, the earth will run out of all non-renewable sources of energy.

The formation of fossil fuels is an incredibly slow process. It was after millions of years, that remains of dead plants and animals deep inside the earth’s crust, were transformed into fossil fuels. Today, fossil fuels are being exploited rapidly, depleting the finite reserves at an unprecedented rate. World consumption of primary energy tremendously increased from 3.8 billion tonnes of oil equivalent in 1965 to 13.17 billion tonnes in 2015. Global warming is keeping in step with fossil fuel usage, as alarming levels of greenhouse gases are released into the atmosphere every day.

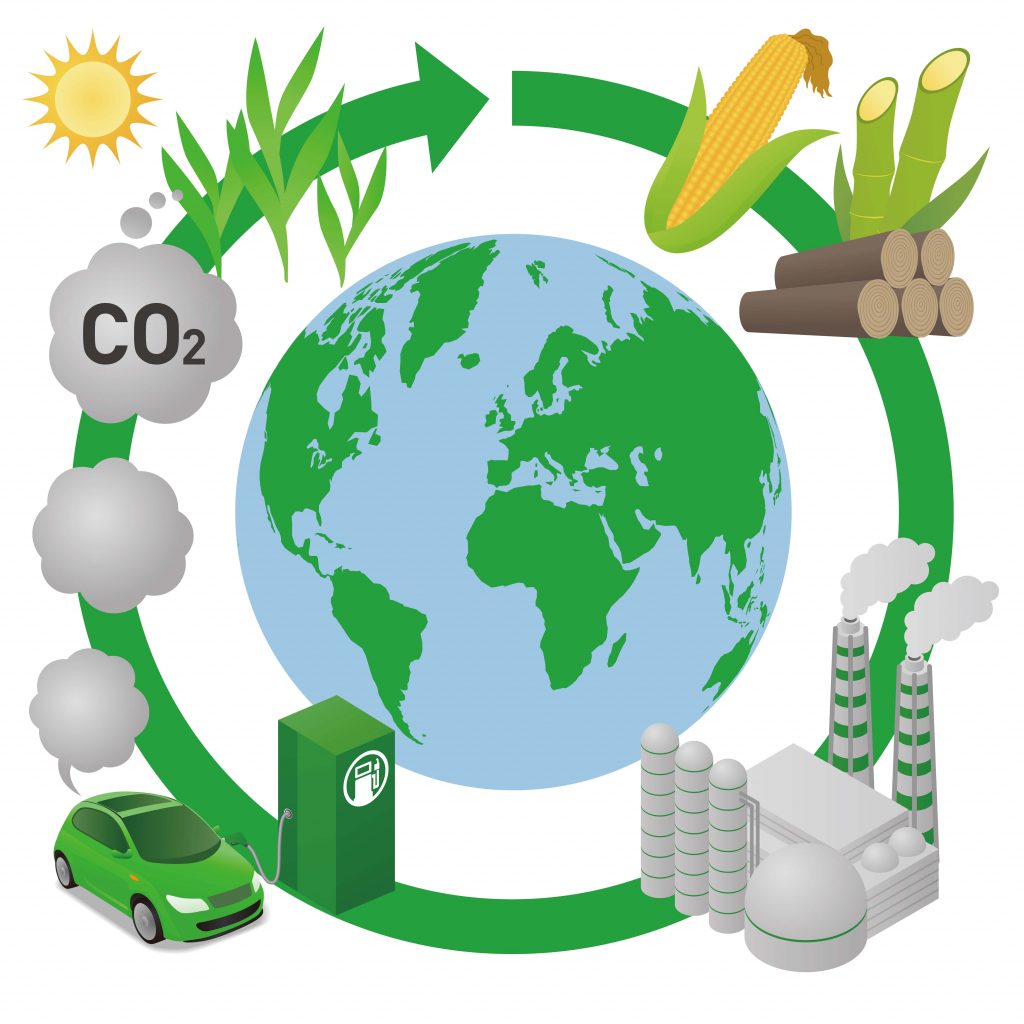

In 2015, India overtook Japan as the world’s third largest consumer of oil. The country is compelled to import over 75% of petroleum products every year. There is a pressing need nationwide to make a switch to renewable energy sources; a move that could be of great significance, both economically and environmentally. Somewhat lesser known alternatives to petroleum products are biofuels — solids, liquids or gaseous fuels produced purely through biological means. A highly promising form of biofuel that has enormous potential in India is biogas.

Biogas can be produced from a variety of materials, including waste products. For example, wastewater sludge and municipal solid waste can be used to produce biogas. One of the major advantages of biogas is that it can be produced from agricultural waste. Soiled bedding from cattle sheds, unconsumed crop residues, fallen leaves, farmyard manure and weeds, all of which are available abundantly in farms, can be used to produce biogas. Hence, practically every farm in India is a potential producer of energy.

Biogas is processed by microbes in anaerobic digesters to produce colorless, odorless, energy-rich gas called methane. However, methane in a gaseous state is difficult to transport from the source. It is more readily conveyed from one place to another when it is highly compressed. And here is one application where air compressors have a role to play in generating and using renewable energy.

Many medium-sized biogas plants have been set up in the state of Gujarat in India with financial support from Ministry of New and Renewable Energy (MNRE) and the state government. One of these plants has been installed in Vadodara, India. At this plant, there are six biogas digesters. The gas is pressurized by a screw air compressor and fed into a scrubbing unit which removes contaminants. The pressure of the pure biogas is raised to 250 bar in multiple stages using ELGi Sauer reciprocating air compressors. This pressurized gas, referred to as bio-CNG (‘Compressed Natural Gas’), is stored in bottles. A ton of waste yields 40 cubic meters of bio-CNG at the Vadodara plant. Half of the gas produced is used to provide street illumination in the community. The rest is available for retailing to industrial applications and transportation needs.

Bio-CNG is similar to commercially available natural gas, in terms or chemical composition and energy potential, but can be made available at a fraction of the cost. It is easy to imagine the changes that could be brought about if such biogas plants are put up all over the country. Biogas could be made widely available at economic rates while reducing India’s dependence on crude oil imports.

With growing awareness of the benefits of bio-CNG, several noteworthy initiatives are beginning to take root in the country. To cite an example, Amul Dairy, an Indian dairy cooperative, became the first Indian food industry to build a fully-functional bio-CNG generating and bottling plant in 2016. In 2017, India’s first biogas bus was launched in the city of Kolkata. With an estimated fare of only ₹1 per ride, this 55-seater bus runs on fuel generated entirely out of cow dung.

There is a long way to go, but slowly and steadily we’re driving towards a greener, healthier nation and biogas could be the fuel propelling us forward. It does not seem unlikely, then, that a few years from now, you may be driving in the countryside in a biogas powered car. There is hope, yet.